Introduction

Dentistry is a field that constantly evolves, and at Topway Dental Lab, we’re leading the charge in innovation. As a full-service outsourcing dental lab, we’re excited to introduce the transformative potential of metal 3D printing in crafting dental restorations that are precise, durable, and tailored to our patients’ unique needs.

The Cutting-Edge Technology of Metal 3D Printing

Metal 3D printing, or additive manufacturing, is a game-changer in the dental industry. Here’s how it works and why it matters:

The Process

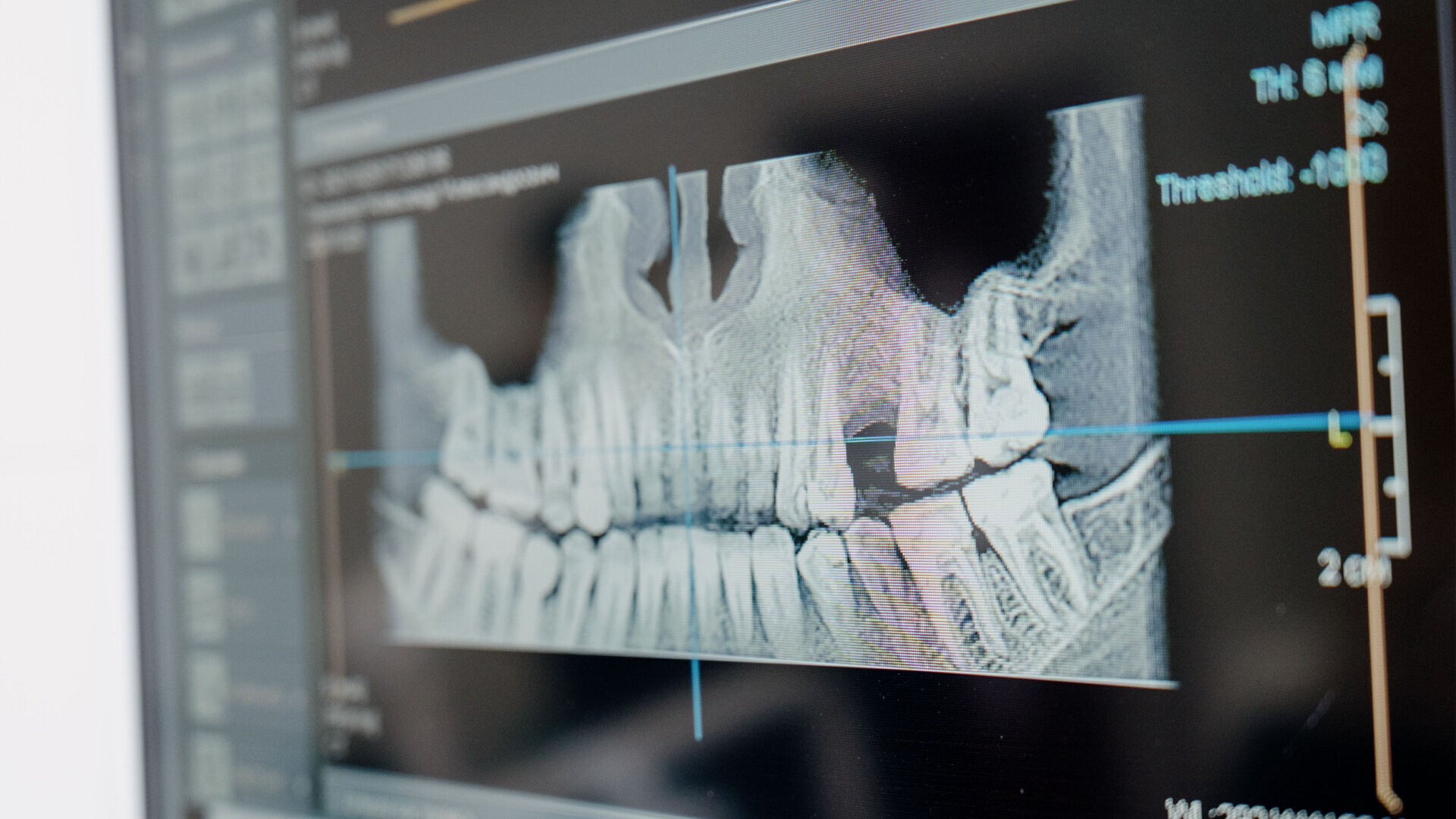

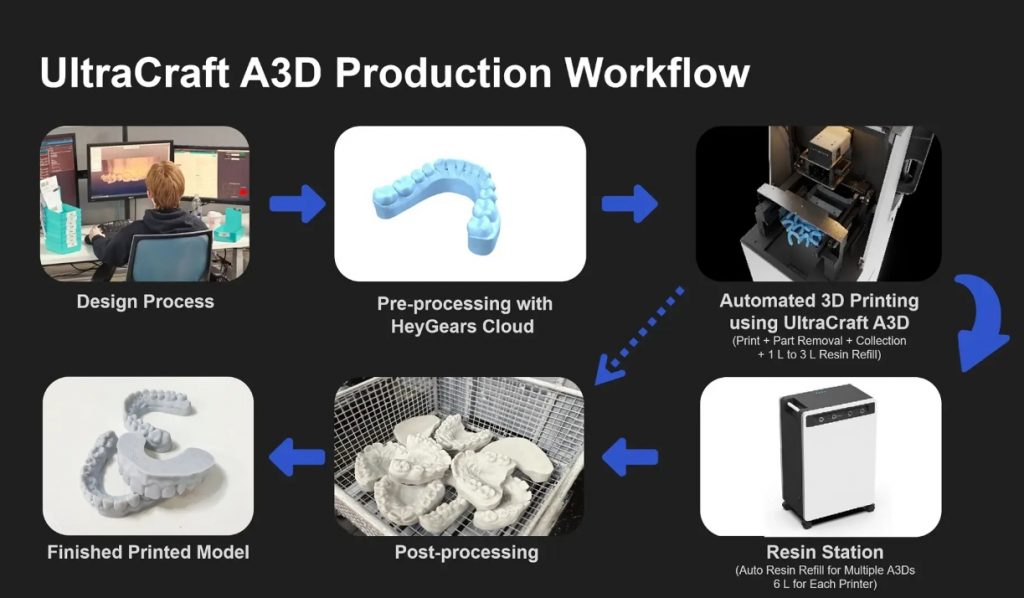

- CAD Design: Our team uses advanced computer-aided design (CAD) software to create a detailed, patient-specific model of the dental restoration.

- Digital Blueprint: The model is converted into a digital blueprint that guides our 3D printer.

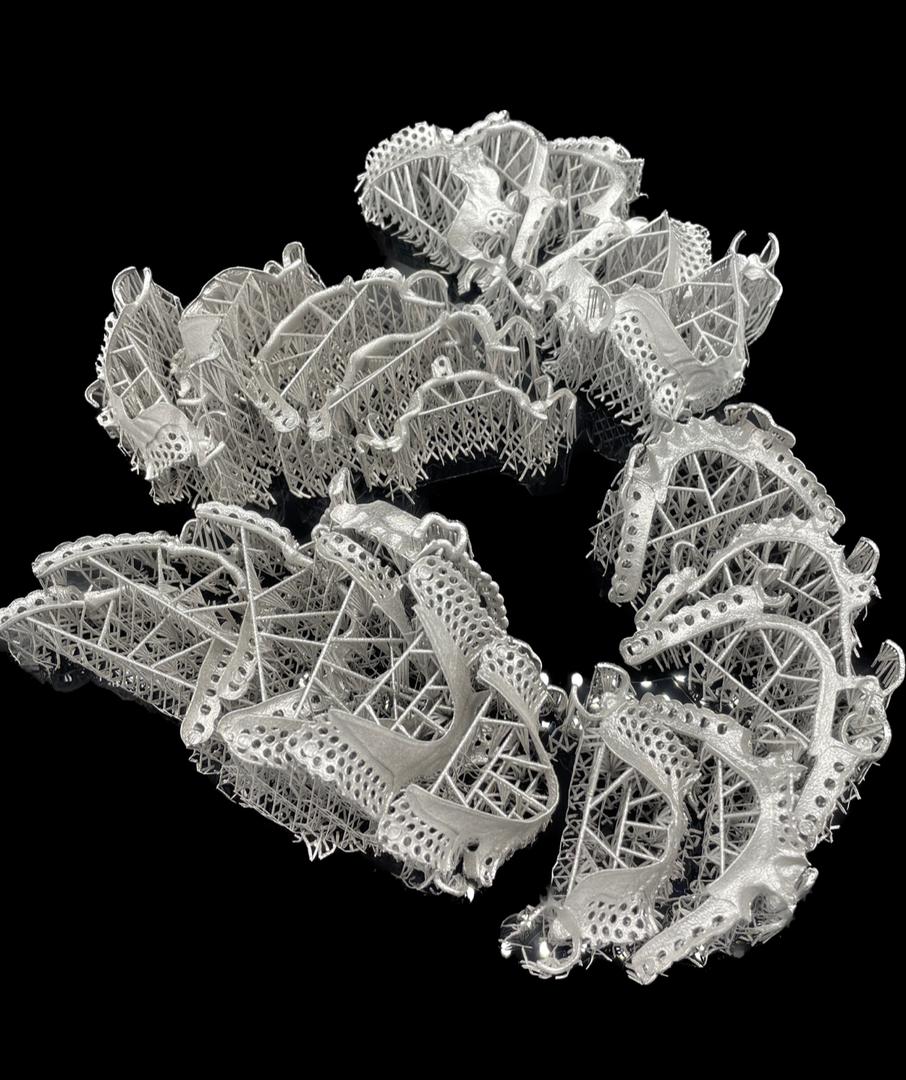

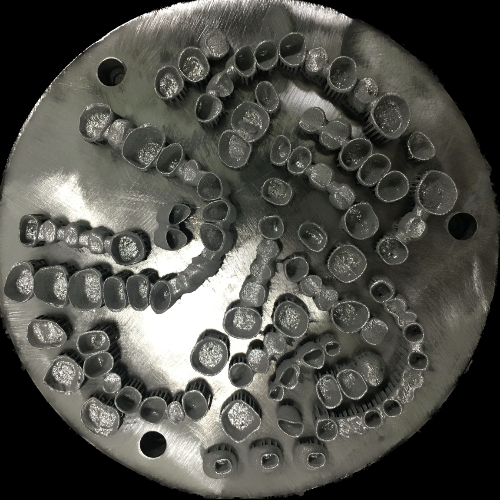

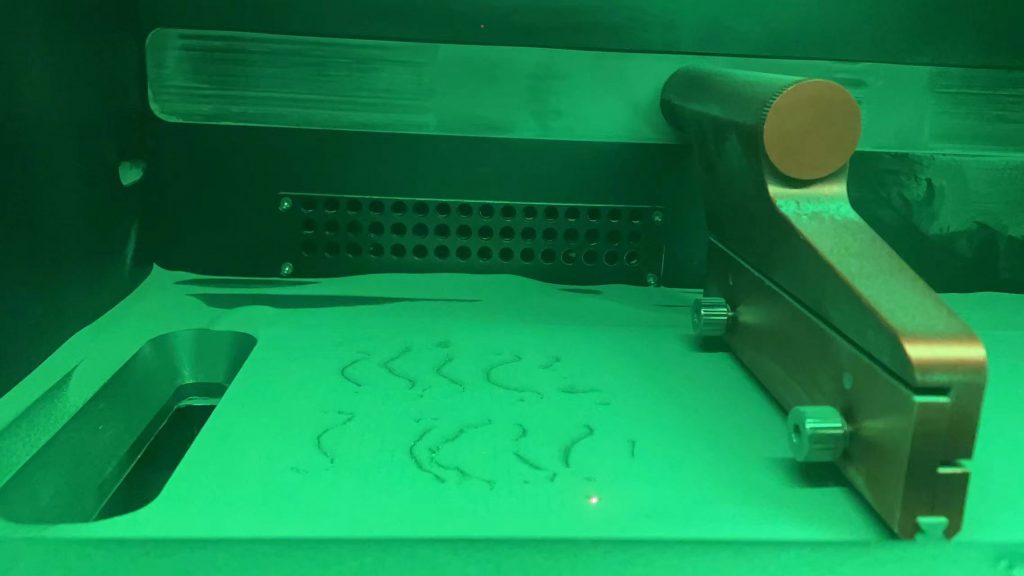

- Layer-by-Layer Construction: A high-powered laser fuses thin layers of fine metal powder, building the restoration layer by layer.

- Post-Processing: The finished piece is carefully cleaned, polished, and inspected to ensure it meets our high standards.

Advantage

- Precision and Accuracy: Metal 3D printing ensures a perfect fit for every restoration, enhancing patient comfort and satisfaction.

- Complex Geometries: We can produce dental prosthetics with complex geometries that closely mimic natural teeth, offering both function and aesthetics.

- Durability: Dental restorations made with metal 3D printing are strong and long-lasting, providing reliable oral health solutions.

- Efficiency: Streamlined production times mean faster turnaround for dental practices and their patients.

Applications in Dentistry

- Crowns and Bridges: Custom-made to fit seamlessly with a patient’s bite and tooth structure.

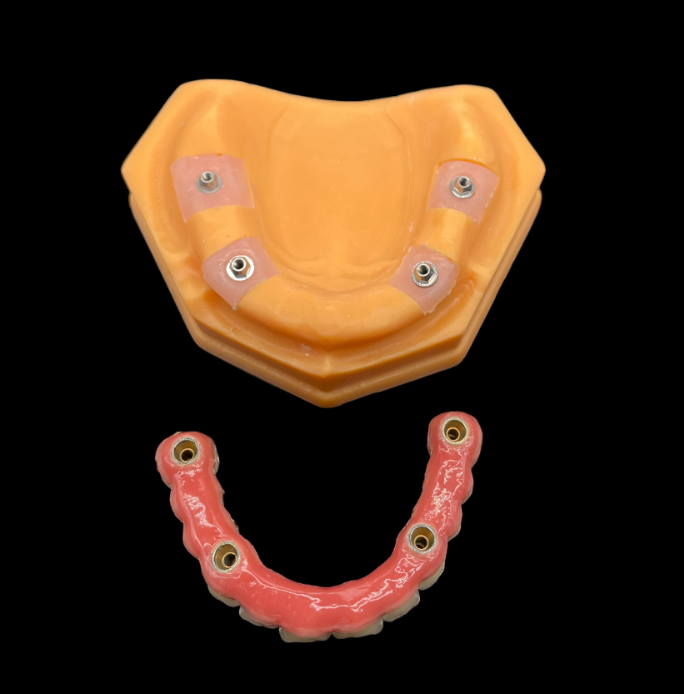

- Dental Implants: Precision-engineered for optimal osseointegration and stability.

- Orthodontic Appliances: From clear aligners to retainers, providing effective and comfortable orthodontic solutions.

- Prosthodontics: Expertly crafted dentures and partials with a focus on detail and comfort.

The Future of Dental Restorations with Topway Dental Lab

As we continue to innovate with metal 3D printing, Topway Dental Lab is committed to:

- Incorporating Biocompatible Materials: Prioritizing patient safety and well-being.

- Integrating Digital Workflows: Enhancing efficiency from digital impression to final restoration.

- Expanding Customizability: Offering an extensive range of personalized dental care options.

Conclusion

At Topway Dental Lab, we’re dedicated to harnessing the power of metal 3D printing to provide our partners and their patients with the highest quality dental restorations. As we forge ahead, we’re excited to bring you the latest advancements in dental technology, ensuring that every smile is crafted with care and precision.

About Topway Dental Lab

As a premier full-service outsourcing dental lab, Topway Dental Lab is committed to excellence in dental restorations. With state-of-the-art facilities and a team of skilled professionals, we’re here to serve you every step of the way.

Tips for the Blog Post:

metal 3D printing in dentistry,” “dental restorations,” “custom dental implants,” and “digital workflows in dentistry.”